Analog to digital and vi.

Scada system architecture ppt.

These systems are different from distributed control systems which are frequently found in plant sites.

Supervisory control and data acquisition scada is a control system architecture comprising computers networked data communications and graphical user interfaces gui for high level process supervisory management while also comprising other peripheral devices like programmable logic controllers plc and discrete proportional integral derivative pid controllers to interface with process plant or machinery.

Scada stands for supervisory control and data acquisition.

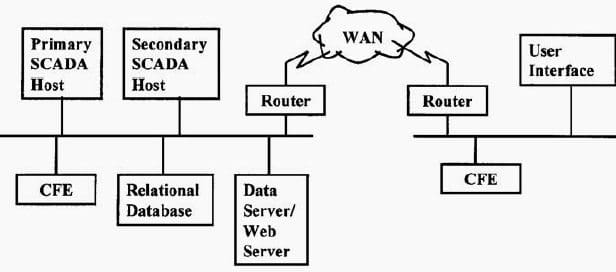

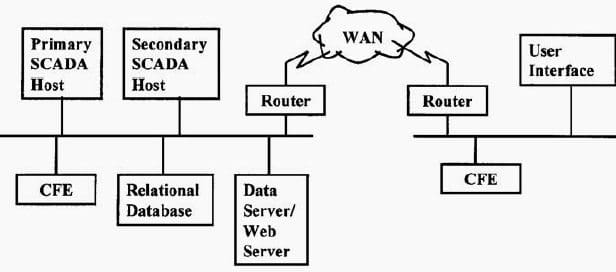

The client layer which caters for the man machine interaction and the data server layer which handles most of the.

Scada system contains two important layers and those are client layer and data server layer.

This post will discuss scada system basic components in detail hardware software architecture types applications advantages and disadvantages.

Power system operation system wide monitoring planning optimisation for reliable and cost efficient operation of the power system time scale.

The term scada stands for supervisory control and data acquisition.

It is an industrial computer based control system employed to gather and analyze the real time data to keep track monitor and control industrial equipments in different types of industries.

Basically consists of data accessing featurebasically consists of data accessing feature and controlling process remotely and controlling process remotely.

Scada systems used to run on dos vms and unix.

The above figure shows the basic scada architecture.

Scada architecture components scada system functions non functional aspects.

Architecture typical hardware architecture.

Architecture hardware architecture one distinguishes two basic layers in a scada system.

Consider the application of scada in power systems for operation and control.

Client layer contributes in man machine interaction and coming to data server layer then it handles activities of process data control.

When these systems protect the plant site scada system protects much larger geographic areas.

Scada supervisory control and data acquisition 2.

Scada supervisory control and data acquisition systems are used in monitoring and control of industrial equipment in various stages such as development manufacturing production and fabrication.

Conversion of data is possible i e.